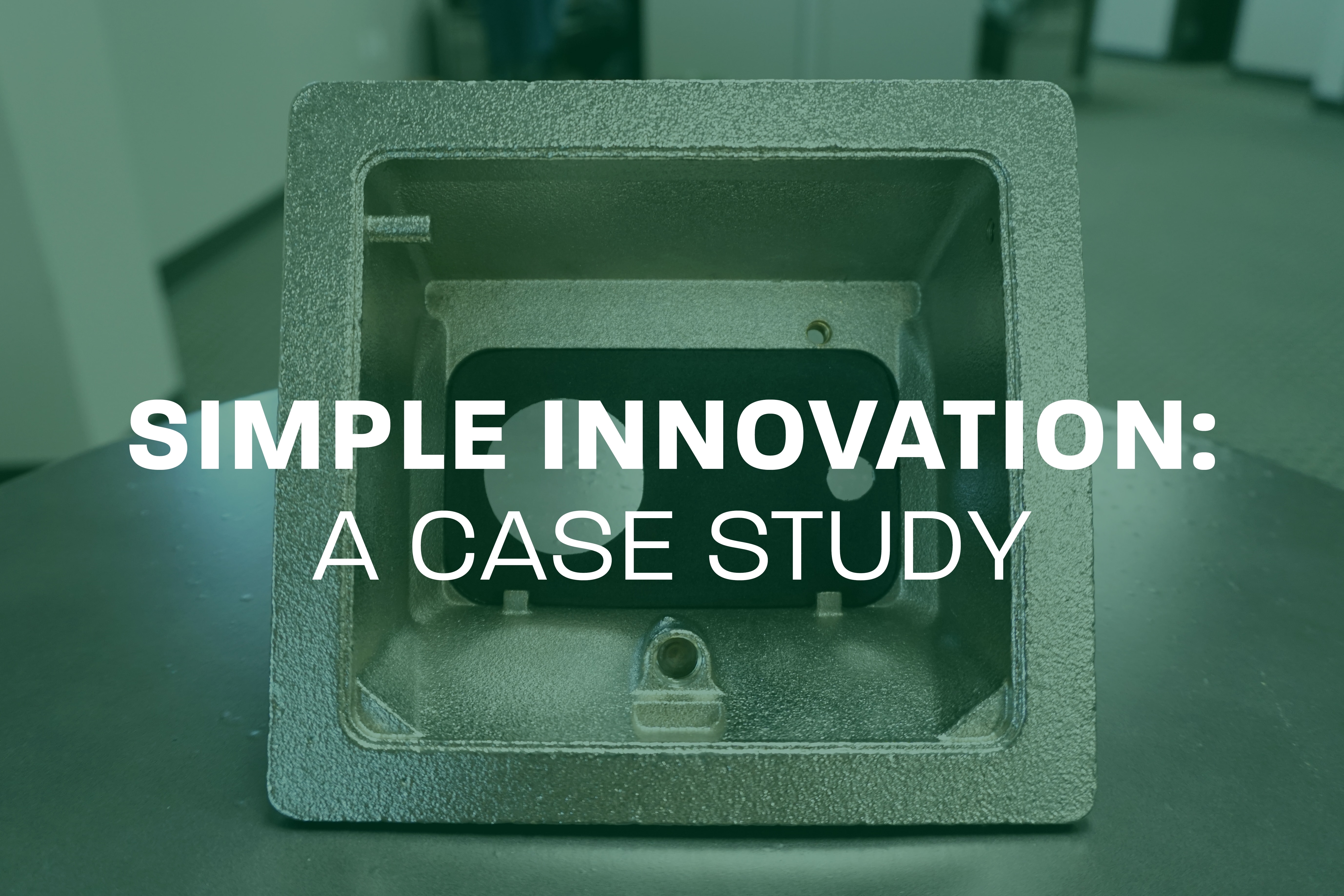

PRIER Products has accepted the challenge and the allure of technology to advance their manufacturing capabilities. In the last couple of years, the company has invested in four Computer Numeric Controlled (CNC) machine tools to manufacture their water hydrant components in-house. This enables the company to have greater control of quality, productivity and easier prototyping for development of future products.

Some background on CNC technology:

The original concept for computer controlled operation was developed at MIT in the 1940’s and 1950’s with the goal to improve quality and efficiency of manufactured parts. It was a very rudimentary system of a manual machine adapted with analog controlled motors. The program was stored on a paper tape with punched holes that the machine interpreted into machine movements. If a correction or change was to be made, the tape had to be re-punched offline and fed into the machine again. The first machines used Numeric Control (NC), which later evolved to CNC as the technology advanced.

Today’s CNC machine tools are fully programmable at the machine or offline on a computer using third party software or proprietary software specific to the machine and transferred to the machine via wire or USB. As well, CNC concepts have been applied to a multitude of types of machines, such as lathes, mills, laser/plasma cutters, routers, water jet, etc. The technology has advanced to include performing multiple tasks (turning, milling, multi-axis contouring, etc.) on one machine tool.

The programming “language” is known as G-code, often referred to as G&M code. Industry standards organizations (EIA in the US) have developed the base system of G-code, while each machine tool builder has added their specific and/or proprietary codes to make their machines unique. The result being that a program written for a specific machine tool will not work on another brand without edits. Another advantage of CNC technology is programming techniques that enable making similar parts for a “family” of parts with similar features (i.e. dual/quad threads) with the same program. Associated with G-codes are M codes, used to control machine functions like spindle on/off, coolant on/off, and other miscellaneous functions.

In the PRIER Products machining department, we currently have approximately ten hydrant components ready to be produced and have several more in development. Over the last two months, we have made improvements to our chip (waste) handling by utilizing chip bins that are easier to move around and more open to transfer chips for cleaning. The greatest result is safer handling of chip containers and reclamation of coolant directly back to the machine. As well, we are setting up a coolant filtration system to clean reclaimed coolant oil to extend the life of the coolant and our machine tools by reducing fine particles.

PRIER Products has been able to utilize machining technology to maintain and improve their components for their world class products. We look to technology to be able to expand the machining department to include more of components for in-house manufacture.

For more PRIER news, visit us on Facebook, Twitter, LinkedIn, Instagram, YouTube and Pinterest!