C-108 | Hot and Cold Mixing Hydrant

PRIER C-108 provides a year round source of tempered water in areas that are subject to freezing temperatures. The hydrant valve is connected to the supply piping in the heated portion of the structure, eliminating the possibility of freezing. Unique to its patented design, the same product can be installed horizontally or vertically. Ordering the C-208 gives you the same style hydrant but with vandal proof extended lockshields with operating key on both hot and cold stems.

The PRIER C-108 has all the characteristics of the historically proven C-134 with the added protection of a self-draining anti-siphon vacuum breaker and backflow check valve. It is available from stock in lengths from close coupled to 24”. Longer sizes are available on request.

You can also easily add an outdoor freezeless shower to your C-108. Check out the C-108SH1.

Or, for a classier and more sophisticated look, check out the P-118.

Features

- Anti-siphon aluminum vacuum breaker with EPDM backflow preventer and backflow check valve

- Internal checks to prevent thermal migration

- Solid brass body, valve stem cap, seat and stem ends

- Satin nickel plated body maintains attractive finish

- Stainless steel screws

- Powder coated cast aluminum handle

- Lock shield cap

- AFG teflon with graphite packing for easy maintenance

- Standard “OO” size seat washer

- Each valve air-tested at factory for leak-free quality

- Spout aligning mark with manufacturer’s date code

Product Support

Possible Repair Issues for the C-108 Freezeless Wall Hydrant include:

1. When the water is running, water leaks out from behind the handle

This is a common maintenance occurrence for any packed valve of any brand or manufacture. It is overcome by simply tightening the packing nut with a crescent wrench. This will force the packing tighter around the stem to eliminate leakage.

Occasionally, the packing will need to be replaced if the packing nut has been repeatedly tightened.

The packing kit required for this reapir is part number C-134KT-803.

C-134KT-803 Packing Kit

2. The hydrant drips after shut off

A freezeless wall hydrant shuts off inside the heated portion of the structure therefore, the water inside the hydrant will drain out after shutoff. The shutoff point could be any distance from 4" to 24" inside the structure. This installation should also be pitched to allow the water to easily drain out of the hydrant. The hydrant may drip for up to 60 seconds after shutoff. If the water continues to drip after that time, you most likely need to replace the bibb washer.

The bibb washer used on this item is a standard "OO" Beveled Bibb Washer, available at your local plumbing wholesaler.

C-134KT-802 Replacement Bibb Washer

3. Water is leaking from the hydrant inside my house

DO NOT OPERATE THE HYDRANT IF THIS HAS OCCURRED.

Please remove the handle to prevent accidental operation until the problem is repaired by your plumber.

4. The handle is missing from my hydrant

For any one of numerous reasons, your handle may be missing. PRIER's handle is unique to our products; it has two flat and two round sides. This style handle mates perfectly with our stem-end for a snug fit and years of reliable operation.

The required handle kit is part number C-134KT-805.

C-134KT-805 Replacement PRIER Handle

For a red handle order C-108KT-805.

6. How do I convert my hydrant to loose key?

Commonly, this change occurs to prevent unauthorized usage of the product. To convert to the loose key vandalproof option, part number C-134KT-804 is required.

C-134KT-804 Loose Key Conversion Kit

7. The stem end is damaged and I cannot operate the freezeless hydrant

Occasionally the stem of the PRIER hydrant gets damaged beyond repair. This is most commonly caused by the hydrant being operated by pliers and damage to the brass on the end.

To determine the proper replacement stem, you need to determine the following:

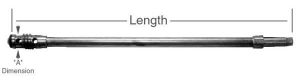

1. Overall length (OAL) of the stem, from tip to brass tip. Do not include the rubber bibb washer in this measurement.

2. The "A" Dimension as shown on the picture below. This "A" Dimension will either be 1/2" or 9/16". A caliper may be necessary to determine this dimension.

3. Using the acquired dimensions, determine which stem is required from the spec sheet.