C-534 | Commercial Design

PRIER C-534 provides a year round source of water to areas that are

subject to freezing temperatures. The hydrant is connected to the supply piping in the heated portion of the structure, eliminating the possibility of freezing. To ensure freeze protection, the hydrant will drain even with the hose attached and under pressure without sprayback.

The C-534 combines freezeless hydrant features with self-draining, antisiphon and two backflow check valves. The vacuum breaker/backflow preventer provides protection against cross-connection of the potable water supply, while venting to eliminate any vacuum. This commercial wall hydrant is key operated, code approved, and flows up to 9 GPM. No special installation tools are required.

Take a look at some of our other products that automatically drain, like the C-434.

Features

- Double check valve and anti-siphon vacuum breaker

- Drains automatically with hose attached

- Short valve stem cap for smaller profile in box

- Integral cast flange with built-in drainage pitch

- Solid brass body, valve stem cap, seat and stem ends

- Satin nickel plated body maintains attractive finish

- Optional stainless steel hydrant box sold separately

- Multiple vent holes ensure proper draining and reduce problems associated with insect nesting

- Designed to last the life of the plumbing system

- Patented PRIER “triple seal” positive shutoff system offers triple redundancy to assure shutoff

- High flow rate, 9 GPM at 25 PSI differential

- Same key operates box lock and hydrant

Product Support

PRIER has been manufacturing the C-534 Freezeless Hydrant since 1992. It is a simple operating product that is fairly simple to repair.

The C-534 Freezeless Hydrant drains with the hose attached and under pressure. To accomplish this, there is a bypass assembly in the hydrant. Possible Repair Issues for the C-534 Freezeless Wall Hydrant include:

1. When the water is running, water leaks out from behind the handle

When the C-434/534 Hydrant is turned into the "off" position, the water in the valve will drain out behind the packing nut. If water leaks from behind the packing nut during operation, the o-ring or u-cup bypass has been damaged and needs to be replaced.

To determine which of the two styles you have, the stem needs to be removed from the valve to identify the bypass type. The bypass will be on the stem, near the handle end.

Current Style-O-Ring:

Old Style-U-Cup:

2. The hydrant drips after shut off

C-434KT-902 Stopper and Pin Kit (with tool and o-ring)

3. The operating key is missing from my hydrant

The required part number is C-108KT-808.

C-108KT-808 Operating Key

4. How do I convert the hydrant to handle operated?

Contents of this kit are as follows:

5. The stem end is damaged and I cannot operate the freezeless hydrant

To determine the proper replacement stem, you need to determine the following:

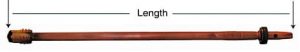

1. Overall length (OAL) of the stem, from tip to brass tip. Do not include the rubber bibb washer in this measurement.

2. Using the acquired dimensions, determine which stem is required from the chart below:

The following stems are for the C-434/C-534 Freezeless Hydrant (manufactured 2007-present):

The following stems are for the C-434/C-534 Freezeless Hydrant (manufactured pre-2007):

5. The stem end is damaged and I cannot operate the freezeless hydrant

To determine the proper replacement stem, you need to determine the following:

1. Length of the stem, from brass tip to brass tip.

2. Using the acquired dimensions, determine which stem is required from the chart below:

The following stems are for the 300 Diamond Series Mansfield Style Hydrant (manufactured after Spring 2013):

The following stems are for the 300 Series Mansfield Style Hydrant pre-Diamond Series (manufactured before Spring 2013):

6. Water is leaking from the holes by the hose thread

The rubber washer inside the vacuum breaker has failed and needs to be replaced. This is accomplished by unthreading the vacuum breaker from the body of the hydrant and replacing the internals. The vacuum breaker is sealed to the body with a body sealant and may require heat to break loose.

The parts required for this is a C-434KT-906 Vacuum Breaker Replacement Kit

Installation Instructions:

To repair the vacuum breaker on any of the above items, it first needs to be removed from the valve. The vacuum breaker is sealed to the valve and needs to be heated with a torch to be removed. Once it is removed you can reinstall the new parts in the order as shown above.

6. I need a complete rebuild kit

Contents of this kit are as follows: